Reference Projects

Our comprehensive solutions fit the needs of our clients to the greatest extent. Our passion is precise engineering, and it shows in all that we do.

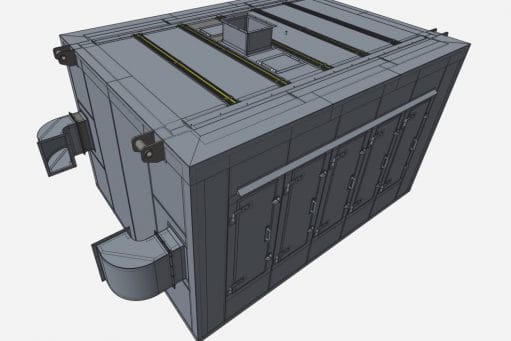

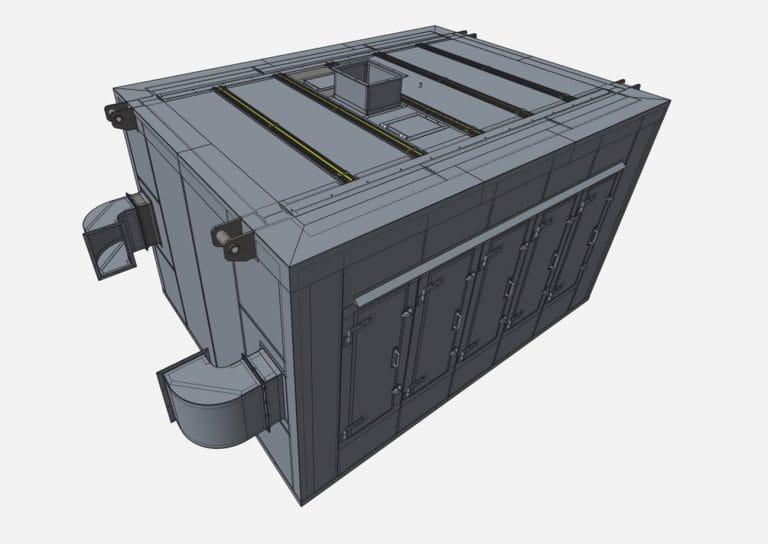

Resin dryer oven

Carbon reinforced parts are increasingly used for the manufacturing of various products. Accordingly, production is also to be accelerated, which is better done by a 5 chamber resin dryer oven as opposed to the preceding 3 chamber variants.

Our task was to design a greater size and capacity oven, also, the previously used light construction device had to be amended with a new, self-supporting frame that can be lifted by crane.

The destination was overseas, consequently, requirements of transportability by road and boat, as well as of repeated movement by crane had to be considered. A recalculation of air channels and the design of a more energy-saving insulation were also parts of our assignment.

We also had to take the order of assembly of the 7 tons machine into consideration. As parts of this size cannot be moved by hand, assembly of the structure is only possible in a specific order; we also provided a well-illustrated manual for the procedure.

-

The challange:

To enlarge inner throughput capacity by maintaining exterior sizes to remain transportable, in a way that a new reinforcement framework also had to fit in and the insulation had also to be improved.

-

Our Solution:

The use of a high-tech insulation material with extra insulating capability, and the design of a framework construction optimized by stress simulation.