Reverse engineering

In line for success!

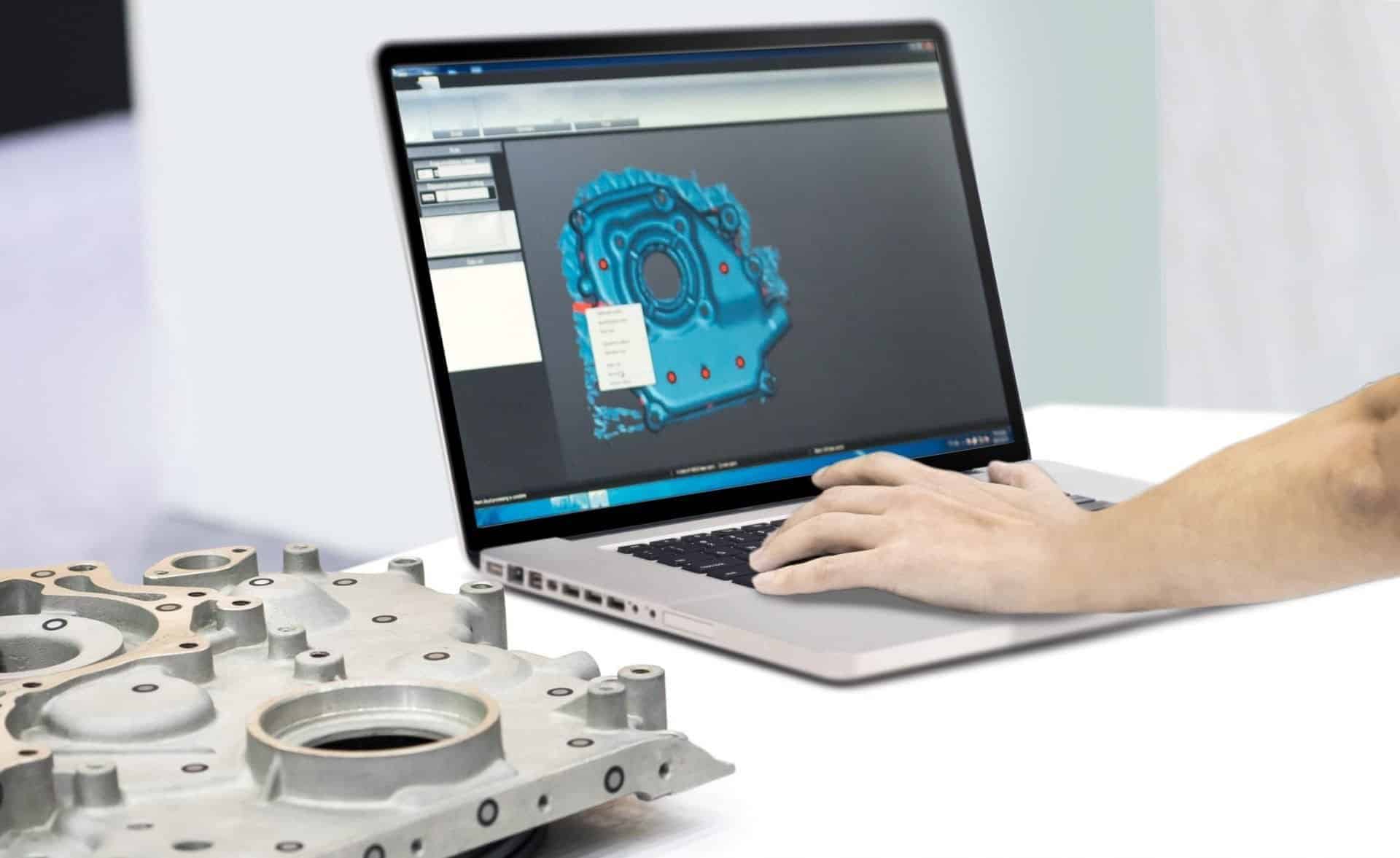

Manufacturing documentation based on a prototype? Transfer of undocumented changes? A worn-out tool without 3D documentation? Our precise and creative team can easily measure, record and remodel in a 3D CAD system. An accurate design drawing and complete documentation necessary for production or authorisation are guaranteed.

Details

-

Parts measurement and recording -

Tool remodelling -

Construction file (based on a prototype) -

Model update

The way we design

-

Measurement

We create a net using the measurement points, then correct unevenness and surface defects.

-

Geometries

Based on the measurement net, we prepare the plane, the cylindrical and other exact geometries.

-

Freeform surfaces

We create the freeform surfaces that are impossible to make using conventional modelling elements.

-

Optimisation

We modify the model on demand in order to develop the concrete workpiece, or to restore the irreparable element during the preparation of the measurement net.

-

Technical design

We prepare 2D designs required for the documentation so that nothing can stand in the way of authorisation and production.

What we are proud of

Take a look at our key projects in which outstanding design and mechanical engineering meet.

-

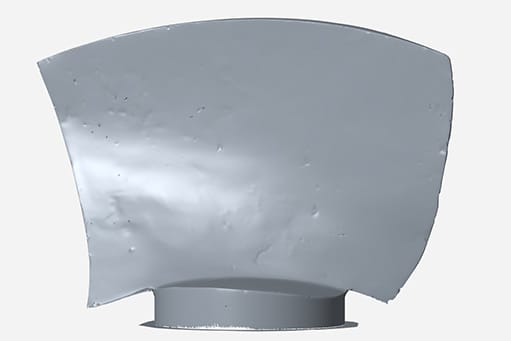

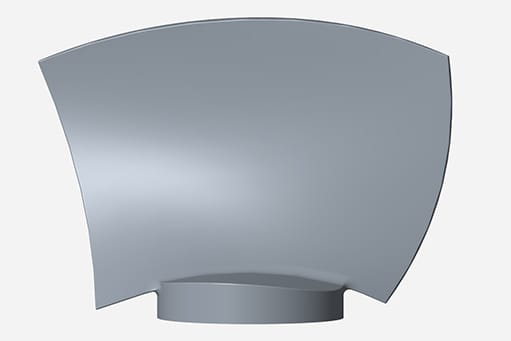

Refitting hydraulic turbine blades

Take a look at the projectWhat happens if the blades of hydraulic turbines get damaged, and there is no documentation? Our special reverse engineering software and experienced engineers make sure to remodel them perfectly.

-

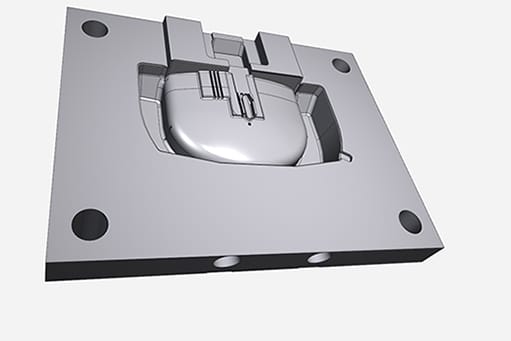

Modelling and repairing an injection moulding tool

Take a look at the projectPrecise digitalisation and remodelling after a fatigue fracture? The biggest difference between the surface modelled by our team and the physical piece did not exceed 0,06 mm, while the average difference was 0,01 mm.

-

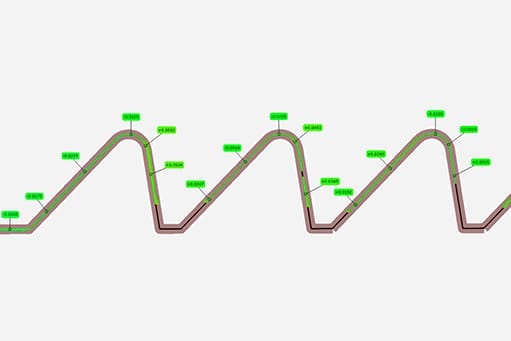

The production of an injection mould thread profile

Take a look at the projectThe modification of the two part union nut without any documentation was done under given connection conditions. The biggest difference between the measured and modelled piece remained under 0,1 mm.

-

Measurement and modification of a foaming mold

Take a look at the projectEven the complete remodelling, then after the reverse engineering process the deepening of the cup side recess (with maintaining the contour) posed no problem for our experts.