Precise measurement anytime, anywhere!

Our team contributes to a perfect visualisation, 3D printing, quality control, size comparison or redesigning required for remodelling in case repairs of broken parts and tools are needed, with quick and complete optical scanning.

-

Designing new parts -

Recording elements with no 3D documentation -

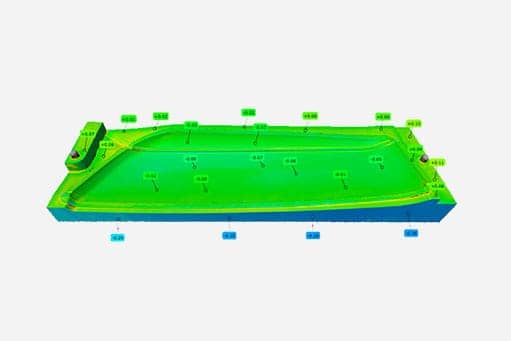

Control of geometric and dimensional accuracy of already finished parts

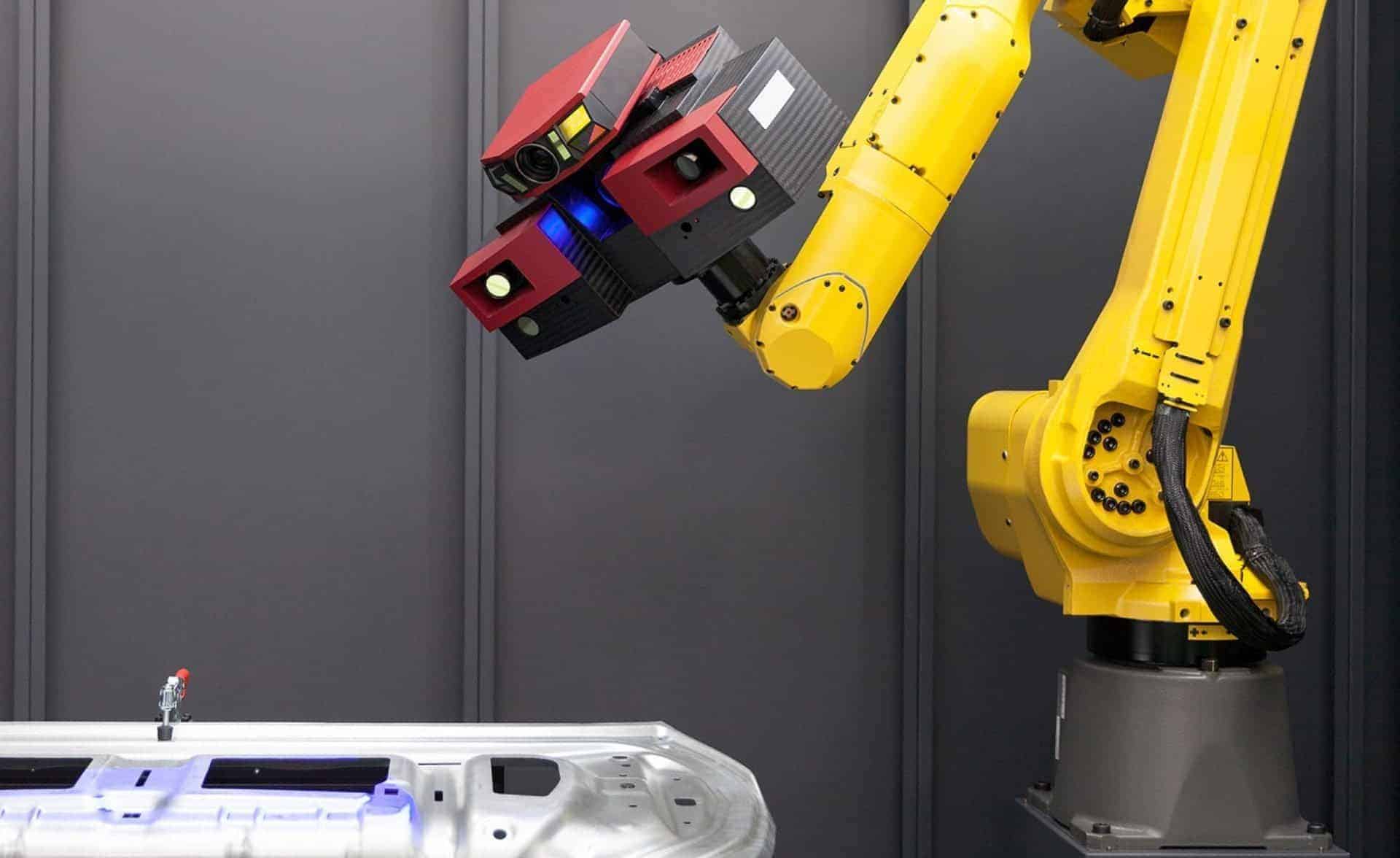

The perfect 3D scanner

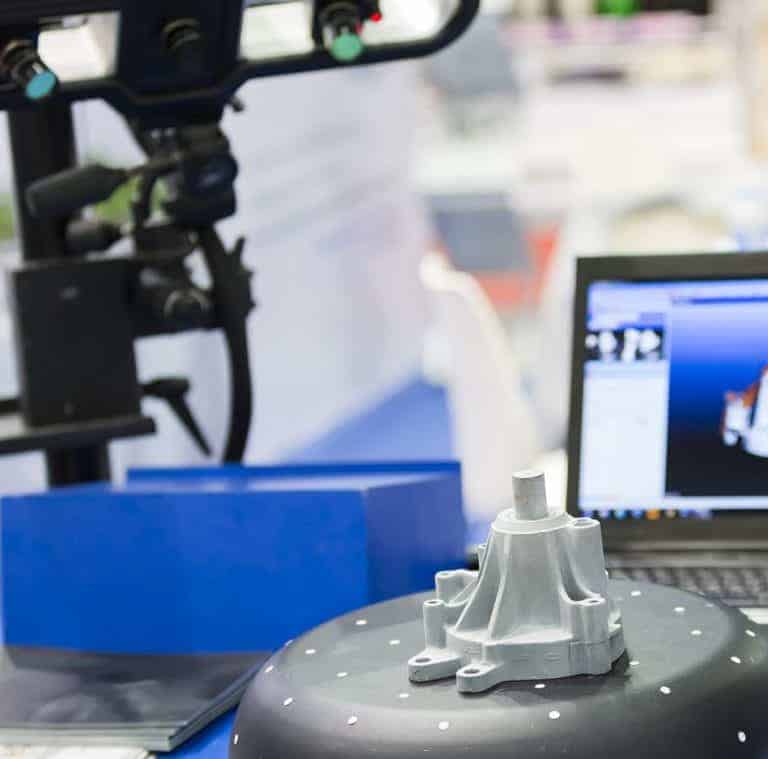

From now on, touchless measurement is also available in case of complicated shape surfaces. Our team is able to measure even whole set-ups with the help of our high-tech GOM ATOS Core 300 optical measuring machine equipped with a stereo camera.

Multiple applications

- For the digitization of components and devices made of any material.

- Usage within a size range of 20-2500 mm.

- The accuracy can reach even the value of 0.02 mm.

- Portable device which can be used anywhere.

What we are proud of

Take a look at our key projects in which outstanding design and mechanical engineering meet.

-

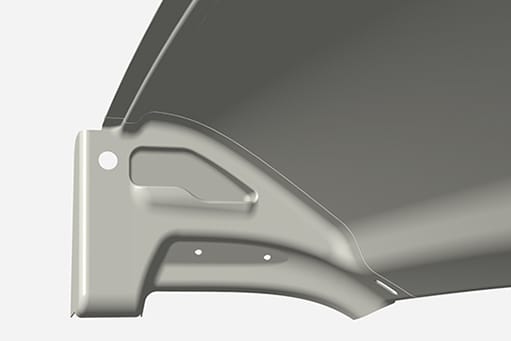

Designing casing for driver cab

Take a look at the projectDesigning casing is not a simple task… We prepared the precise model of the body of an RV using our optical measurement device, the measurements were done under industrial conditions.

-

Measuring and comparing an elbow-rest casing and its tool

Take a look at the projectThere were issues with the assembly of a renown German car manufacturer’s polyurethane foam elbow rests. Our measurements proved that it was not the tool but the manufacturing technology that needed to be modified.

-

Updating a product model

Take a look at the projectModifications without documentation were made on a vacuum forming tool. We modified and updated the 3D model based on the measurement of the tool at the client’s site.

-

Remodelling of a broken tool

Take a look at the projectIs the task to produce a new tool without the required documentation, or is it to complement incomplete documentations? We are able to prepare correct size and form documentations of real workpieces with our measurement device.