Finite Element Simulation

Optimisation at its best

Our team can contribute to the success of your construction with quality CFD and FEM services, with thermodynamic and hydrodynamic, as well as structural and modal analysis; contact and nonlinear, fatigue and life cycle estimation.

Details

-

Thermodynamic and hydrodynamic simulation -

Stress analysis

Simulation process

-

Defining the problem

The first step to success comprises collecting important questions, defining the system to be explored, and recording the objectives of the examination.

-

Defining parameters

The examination of basic characteristics, input and output parameters is essential for optimisation.

-

The simplified model

A cost- and time effective model must be detailed enough to show the parameters to be studied.

-

Validation

The examination of the results of the model is possible by comparing the results of experiments done on the real, hands on system, and of appropriate experiments conducted on the model.

-

Optimisation

In case the results are reliable, the model may be developed also without the production of an actual prototype, by merely changing the parameters.

-

The result

After drawing the applicable conclusions they are documented. Our experts make a recommendation for the development of the construction, and they perform all necessary modifications.

What we are proud of

Take a look at our key projects in which outstanding design and mechanical engineering meet.

-

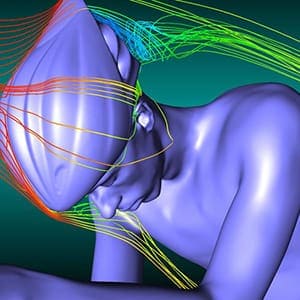

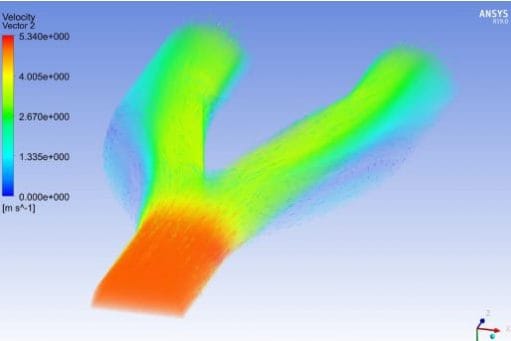

CFD analysis

Take a look at the projectOur experts using finite element hydrodynamics simulation had no difficulties defining the hydrodynamic characteristics of the hydrotechnical elements. We were able to decrease loss of pressure by optimising the geometry.

-

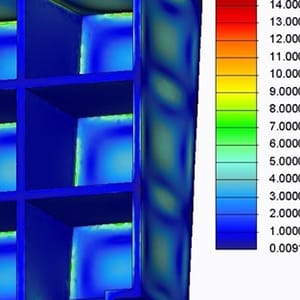

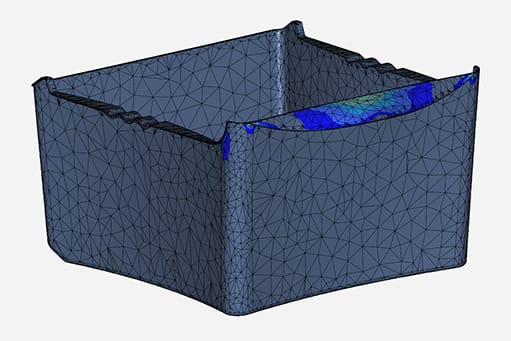

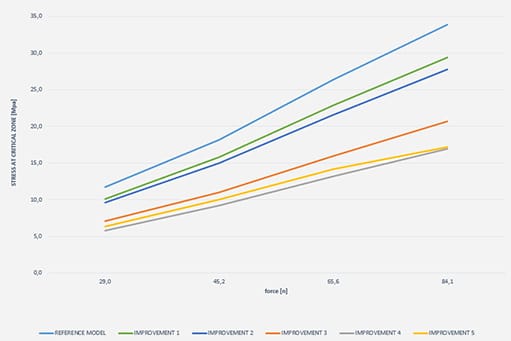

Reinforcement of a drawer

Take a look at the projectA solution for reducing tension. The maximum tension appearing in the critical zone of the drawer decreased by 50% when applying an identical load.

-

Snap fit profile

Take a look at the projectWe conducted a stress analysis to ensure a secure, faultless and long term operation. This way the design of an appropriate material quality (aluminium) snap fit profile and the optimisation of the geometry were fairly simple.

-

Design of a stair step for a caravan

Take a look at the projectRugged but lightweight? The sophisticated stair step designed onto the tow bar of a caravan performed outstandingly not only as far as maximum load is concerned.