Prototype construction

A perfect prototype step by step

Our team ensures an outstanding performance by involving manufacturers specialized in CNC machining, laser cutting, sheet bending, welded structure manufacturing and 3D printing, during the design, manufacturing and assembly of prototypes made of the perfect combination of metal, wood and plastic.

Details

-

A wooden prototype made with a CNC milling machine -

A prototype made with 3D printing -

A prototype assembled of sheet metal parts -

A prototype made by turning, milling and welding

The way we design

-

Product design

Product design often starts with a draft drawn on a piece of paper by our clients.

-

Choosing the technology

We define by what kind of technology the prototype can be produced cost-effectively.

-

Modification and documentation

As the prototype is usually made using a technology different from the final product, some modifications may be necessary.

-

Manufacturing

The parts are manufactured after implementing technical requests and suggestions.

-

Inspection and assembly

After an inspection of the manufactured pieces the prototype is assembled, then the appropriate conclusions are drawn.

What we are proud of

Take a look at our topmost projects displaying a high level of (cost-)effectiveness.

-

Prototype of a refrigerated display cabinet

Take a look at the projectHow is it possible to produce an inexpensive prototype quickly, for the purpose of a trade show for example? If you charge our team, then we accomplish it with state-of-the-art technology.

-

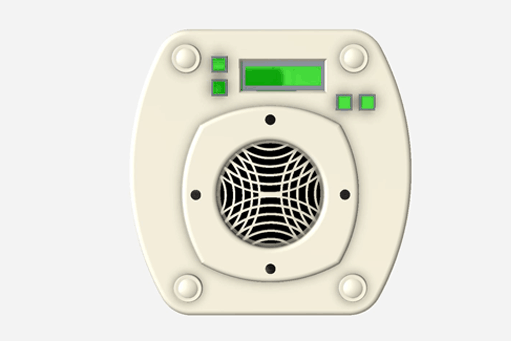

Prototype of an electrical device

Take a look at the projectWe construct prototypes with Zortrax M300 Dual 3D printer with dual-extrusion technology, enabling you to choose from more than 80 different plastics.

-

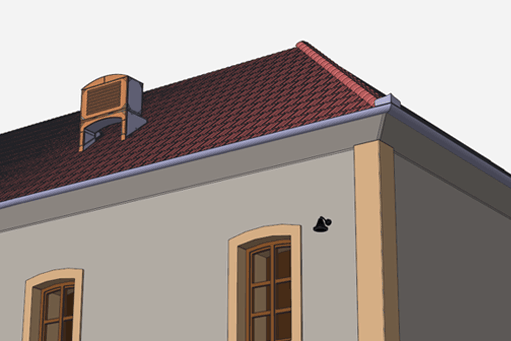

Housing for an air conditioning unit on a tile roof

Take a look at the projectHow is a modern inverter air conditioning device made invisible on a historic building? With a housing which perfectly fits the style of the roof of the historical building.

-

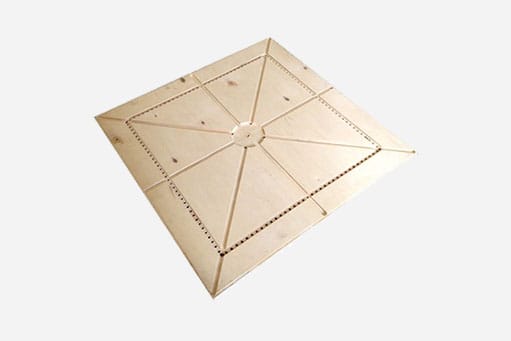

Prototype of a vacuum forming tool

Take a look at the projectManufacturability and easy assembly are the base, a neat design is the bonus. We will only give you a perfect prototype.