Reference Projects

Our comprehensive solutions fit the needs of our clients to the greatest extent. Our passion is precise engineering, and it shows in all that we do.

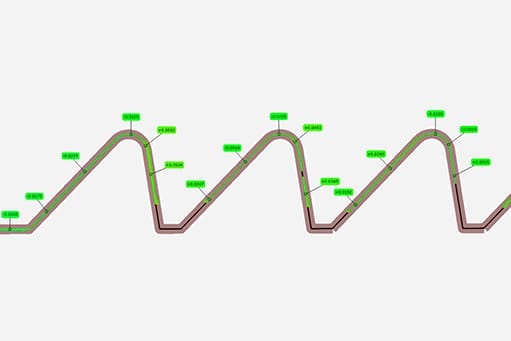

The production of an injection mould thread profile

Our team got the task to do a modified redesign of a two part union nut that connects accurately to an existing, threaded pipe connection. The newly designed union nut had to press a pipe with different diameter and collar thickness, but with an identical size T seal.

As there were no documents about the old injection mould union nut thread available for us, we had to measure and remodel it as accurately as possible. The biggest difference between the measured and the modelled piece remained under 0,1 mm, while the average difference remained under 0,05 mm. This has no practical significance whatsoever in view of the present usage. The seal and the pressure worked perfectly even with the 3D printed prototype.

-

The challange:

To create a well-functioning union nut connection while adhering to geometrical constraints.

-

Our Solution:

Precise optical measurement, modelling true to the geometry, and a virtual check of the connection.