Reference Projects

Our comprehensive solutions fit the needs of our clients to the greatest extent. Our passion is precise engineering, and it shows in all that we do.

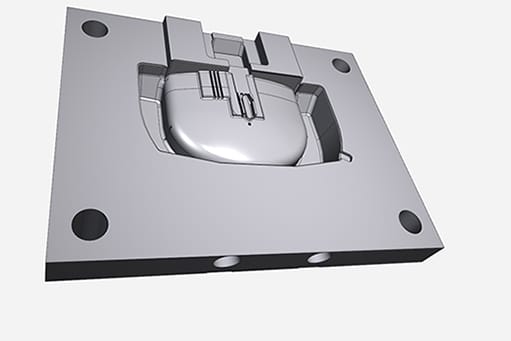

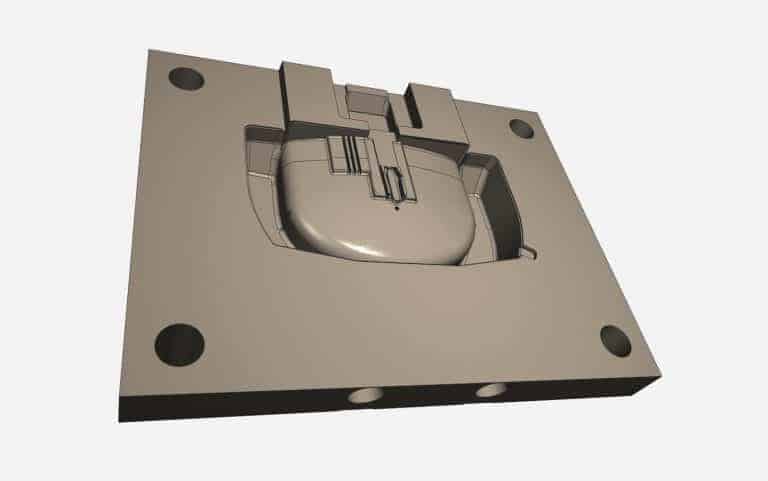

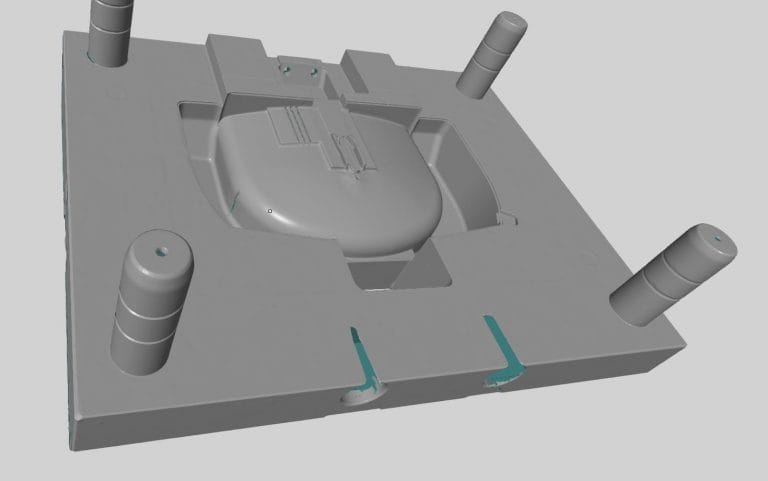

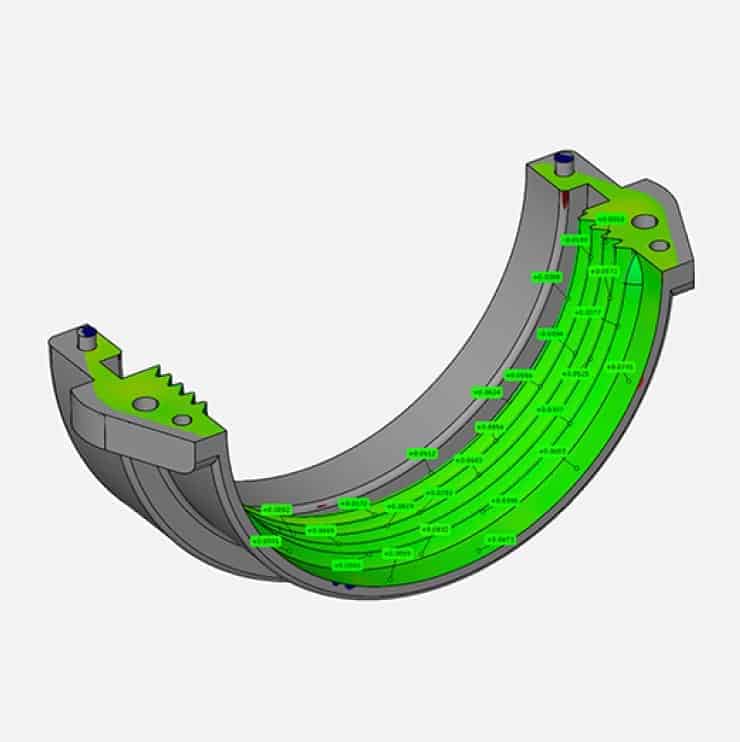

Modelling and repairing an injection moulding tool

The injection mould tool of a plastic part suffered an fatigue fracture around its injection point. To exchange both half tools would have meant enormous costs, therefore we got the job to digitalise and remodel only the broken half.

We had to recreate the intermediate form surface in a way that instead of the deformation and cracks we get a continuous surface. The biggest difference between the surface produced and the physical piece did not exceed 0,06 mm, while the average difference was approximately 0,01 mm.

-

The challange:

An appropriate connection to the other worn out half tool, and the correction of the damaged surfaces.

-

Our Solution:

Creation of complex surfaces, and precise modelling of the connecting surfaces.