Reference Projects

Our comprehensive solutions fit the needs of our clients to the greatest extent. Our passion is precise engineering, and it shows in all that we do.

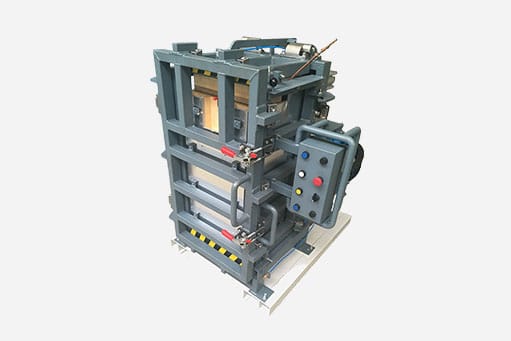

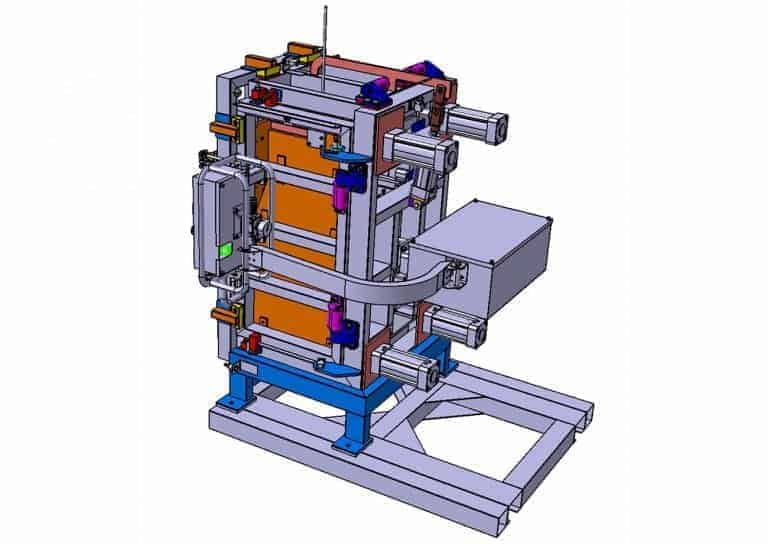

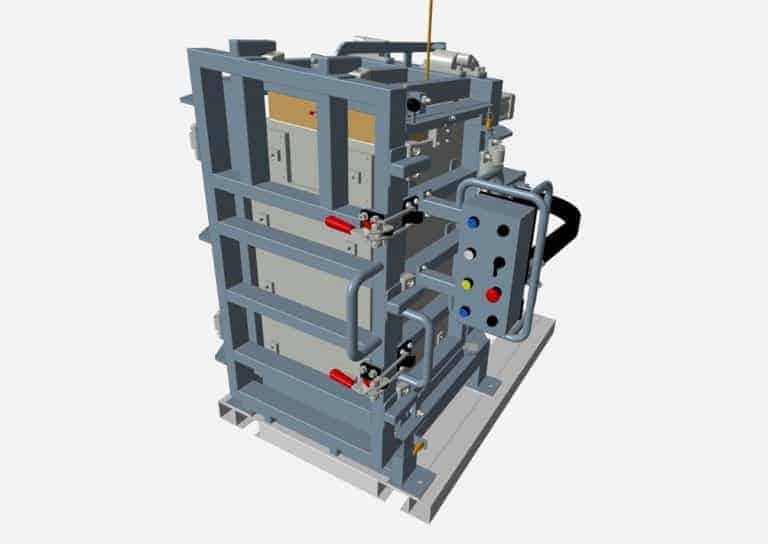

Pneumatically controlled foaming jig

We were tasked with designing a refrigerator foaming jig for a newly designed refrigerator that is of greater size than previous models of the manufacturer. The jig had to fit into the mainly hand operated foaming system and methods of the client, and at the same time to ensure appropriate safety as opposed to other jigs used so far.

Because of its huge mass resulting from its size machine actuation was required, but this could only be pneumatic in order to avoid sparking. A key requirement was to be able to move the foaming jig independently. High safety requirements were met by using pneumatic control and ergonomic design, we also included moving inserts on the core because of the undercuts.

-

The challange:

An easy-to-use, automatically operating tool with moving inserts.

-

Our Solution:

Engineering the pneumatic system thoroughly, keeping ergonomics and safety in mind.