Reference Projects

Our comprehensive solutions fit the needs of our clients to the greatest extent. Our passion is precise engineering, and it shows in all that we do.

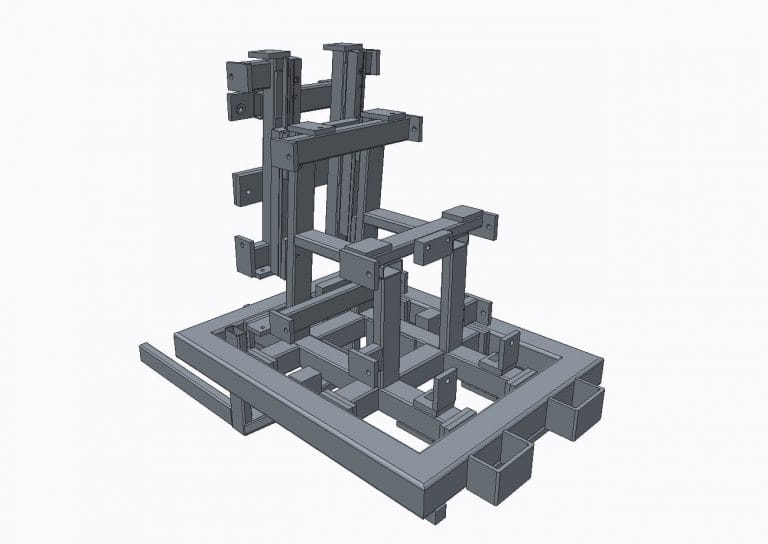

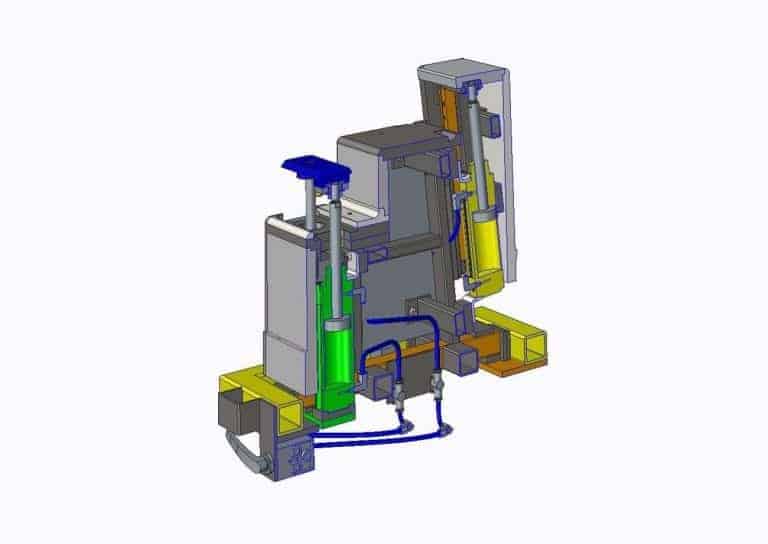

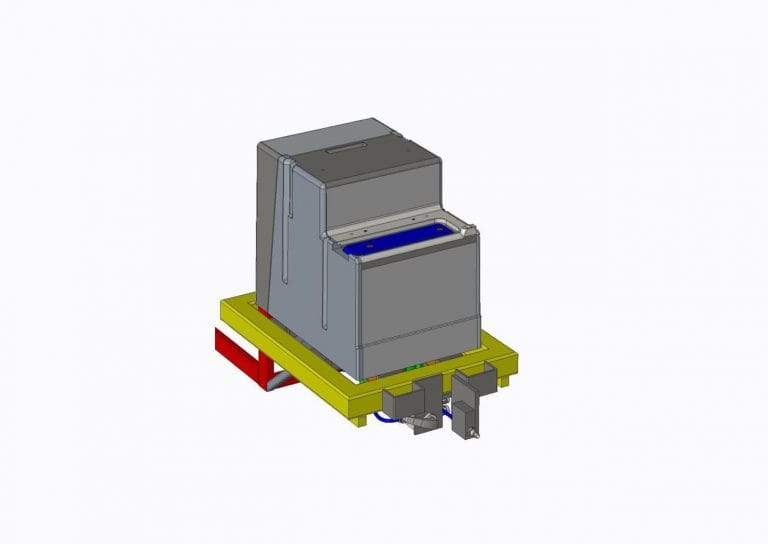

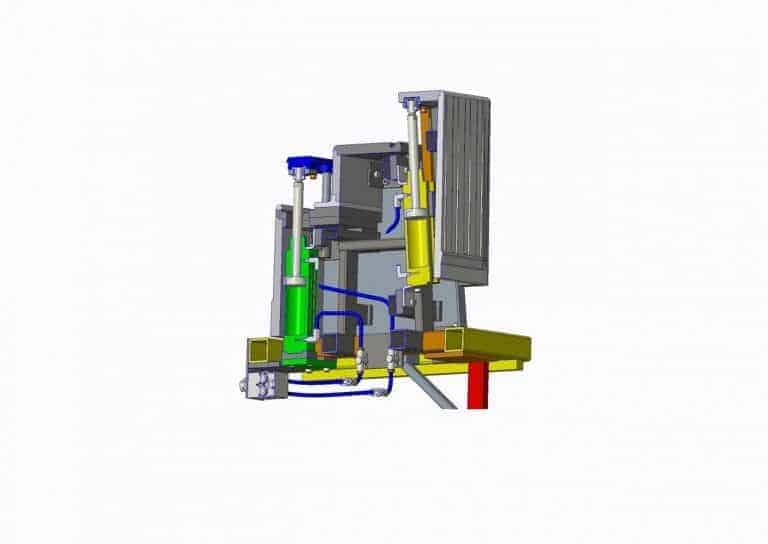

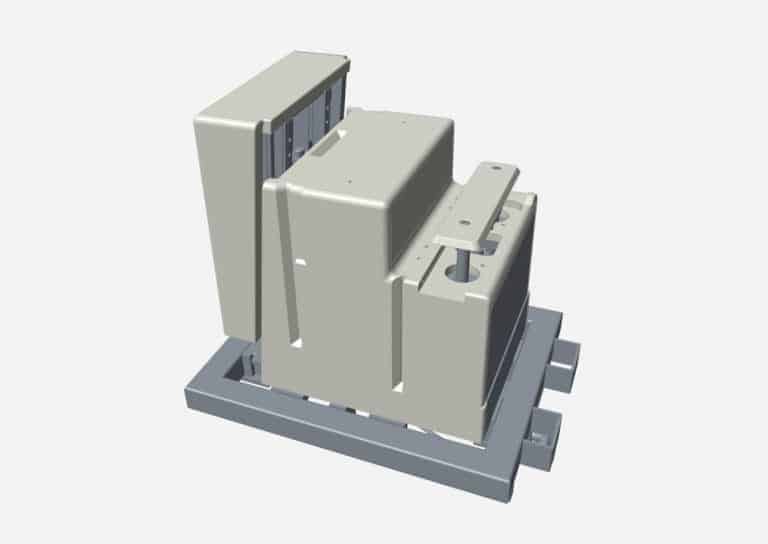

Supporting core

The design of a new supporting core became necessary during a cost reduction project, because the old core didn’t support the corners of the reduced material thickness vacuum formed part.

The solution is the design of a support that holds corners and edges, so that the vacuum formed part cannot cave in under the foam pressure. A perfect nesting was necessary for the plastic part, we solved this with a preliminary optical measurement, and follow-up optical validation.

The workpiece is undercut in the direction of ejection. A seamless ejection next to the precise nesting and the reliable functioning is ensured by the special construction of the tool. Operating temperature: 70 °C.

-

The challange:

The cost-effective solution and the undercut areas.

-

Our Solution:

The shaped surface is made of machined and precisely nested aluminium plates, the ejection of the counterdraft areas is facilitated by an angular ejector.