Reference Projects

Our comprehensive solutions fit the needs of our clients to the greatest extent. Our passion is precise engineering, and it shows in all that we do.

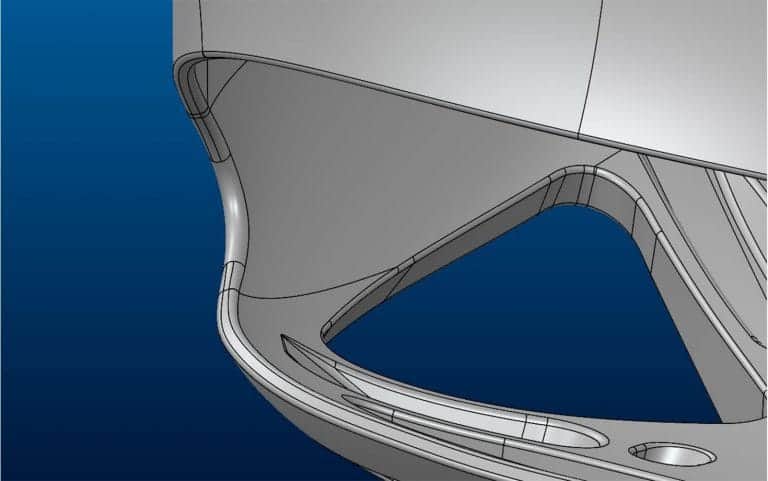

Design swivel chair

3 dimensional design has ensured new options for designers that were unavailable earlier. Even the shape of a glazed chair carved from a tree trunk may be modelled by complex free form surfaces, at the same time posing major challenges for the experts manufacturing the chair and tooling the machines required.

All this was complemented by the special manufacturing technology of our German client which enables extremely wide wall thickness ranges in plastic foam injection moulding, without inclusions or imbibition.

The hidden configuration of the dividing surfaces during the ready-for-tooling engineering of a one piece, injection mould, design swivel-chair is a very demanding task. During the machine engineering of the cavities of the mechanical and connecting parts we had to take the tilting mechanism of the swivel chair into consideration. Also, the form surfaces had to be finished fulfilling the strictest surface quality requirements.

-

The challange:

Easy tooling while fulfilling the strictest surface quality requirements.

-

Our Solution:

Choosing the perfect tooling direction, and a continuous quality control of the curves and surfaces.