Reference Projects

Our comprehensive solutions fit the needs of our clients to the greatest extent. Our passion is precise engineering, and it shows in all that we do.

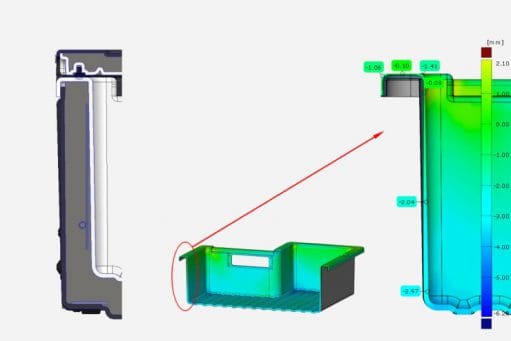

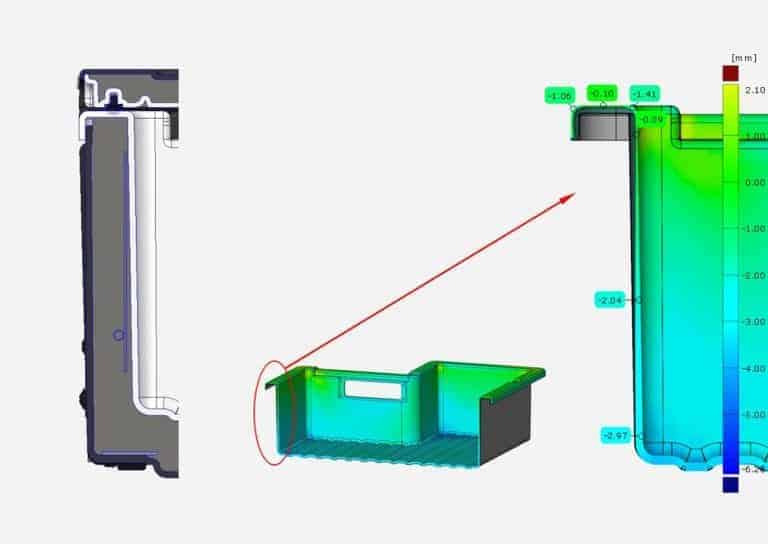

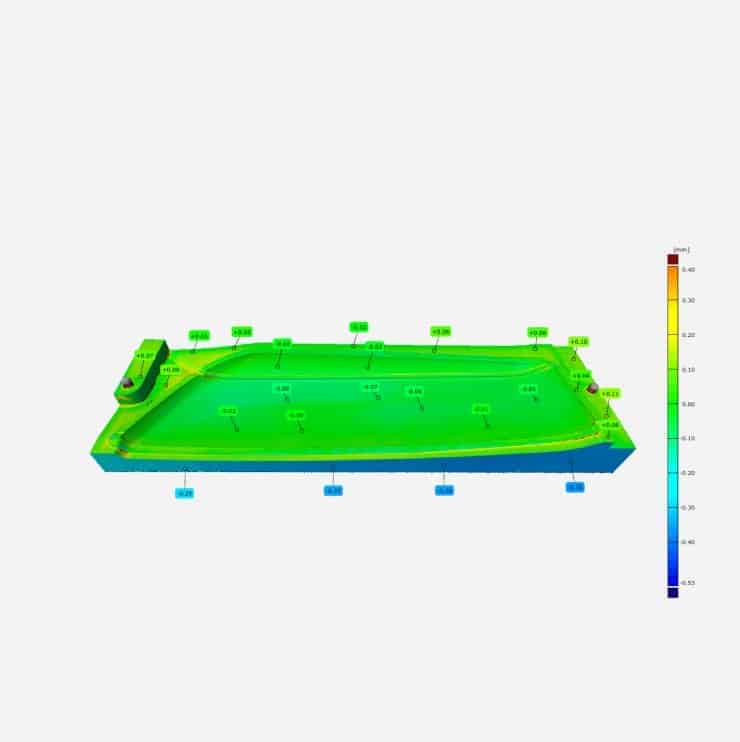

Control of true size and shape

It is often the case with more complex devices that the last piece will not fit into its place, however, it is probably not this piece that is at fault. We often face this issue with vacuum formed products, because the size and shape of a piece is influenced by a large number of parameters.

Many elements can be measured by optical scanning in a few days, and all can be compared to the original CAD model. We are able to visualize with our evaluation software, where and to what extent there is a difference on the piece; we can also prepare a measurement report on our findings. More complex assembly issues can also be solved by using this method.

The expected results often come around not by correcting the faulty part, but by modifying another (e.g. smaller or cheaper) connecting element. We can make a suggestion on which component is worth modifying as far as cost effectiveness is concerned. We can even conduct necessary repairs if required.

-

The challange:

Fitting strongly deformed, vacuum formed parts with regular 3D geometry.

-

Our Solution:

The most precise fitting possible, the drawing of thoughtful and correct technical conclusions.